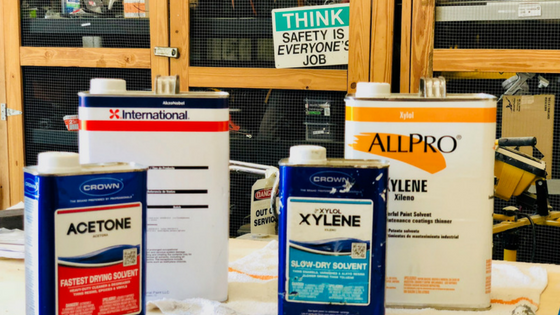

According to experts, numerous workplace accidents and injuries can result from improperly handling and storing hazardous materials, including industrial solvents. One way to keep your employees and customers safe during painting operations is to implement the basics for safe handling, storage, and disposal of solvents, also known as paint thinners.

To help, here is a breakdown of the safety measures and procedures professional industrial painting contractors use when handling and working with industrial solvents.

Work Practices

Besides learning the proper techniques and skills to do their jobs, industrial painters undergo continuous safety compliance training. During training programs, they learn to perform different tasks according to industry-specific regulations, OSHA standards, and safety procedures established by each company. These include, without being limited to:

- Carefully working with industrial solvents and other hazardous substances to avoid splashing and spurting;

- Using the right containment methods and keeping containers tightly closed to prevent the release of toxic vapor/dust in the atmosphere;

- Using the smallest amounts of materials necessary for each task;

- Keeping work and storage areas clean and clear of debris and leaks to reduce the risk of contamination, fires, and explosions;

- Inspecting containers regularly for leaks or damage;

- Properly separating incompatibles, labeling and marking hazardous materials/waste, and storing them in cool, dry, and ventilated areas;

- Disposing of and/or recycling hazardous waste in a responsible and approved manner, according to EPA’s industrial waste management practices;

- Keeping suitable emergency equipment (e.g. fire extinguishers, first aid kits with eyewash and/or shower stations, etc.) readily available and planning ahead by preparing for things that can go wrong during a painting project, such as leaks, spills, fires, and injuries;

- Indicating the actions to be taken by staff, including emergency evacuation, medical, and reporting procedures, in the event of hazardous chemical releases and spills, fires, explosions, and chemical-related injuries;

- Identifying and reporting right away potential hazards, like damaged containers, inaccurate/illegible labeling, ventilation failure, leaks, etc.

Additionally, industrial painters should know what materials are used during each painting project and understand the potential hazards associated with each type of solvent. These include the health and environmental effects, chemical reactivity, incompatibility, and risk of fire/explosion.

Workers should also review the labels and Safety Data Sheets of the coating products they’re not familiar with and use each product solely for its intended purpose. Aside from being one of the leading causes of workplace accidents and injuries, improper handling of hazardous substances can lead to penalties for non-compliance with applicable laws and regulations.

Personal Protection Equipment (PPE)

When working in enclosed and confined spaces, it’s advisable to replace paint products that contain harsh industrial solvents with less hazardous substances. But regardless of whether non-toxic substitutes are available, wearing proper PPE and implementing the right control measures can eliminate worker exposure to toxic vapors, airborne dust, fumes, and mist.

While PPE typically includes safety goggles, gloves, coveralls, barrier creams, and approved respirators with adequate filters or cartridges for industrial solvents, one of the most important control measures is to use well-designed and properly maintained ventilation systems.

When selecting adequate exposure control methods for an industrial painting project, the following factors should be considered.

- The physical state of the hazardous material, like solvent in liquid or paste state (mixed with paint);

- Chemical properties, including toxicity, incompatibility, etc.;

- Potential routes of exposure (e.g. inhalation/skin absorption) and health effects (e.g. eye/skin irritation, ocular/airway inflammation, etc.);

- Application requirements according to each painting project (application by air-spraying, airless spraying, roller, brush, etc.);

- Whether the paint will be applied outdoors and indoors; if the project involves work in enclosed and confined spaces, the size of the area is critically important in order to determine the right combination of exposure control measures;

- The safest way to handle, store, dispose of, and/or recycle the coatings and industrial solvents used during a painting project.

This is just a basic list of safety rules industrial painting contractors follow in order to ensure everyone’s safety during painting operations. Company-specific standards can be added to this list, based on the requirements of each industrial paint job. To learn more about the importance of the health and safety standards in the painting industry, please contact our professionals today!